The Bandsaw jewelry box

beauty inside and out

What is it?

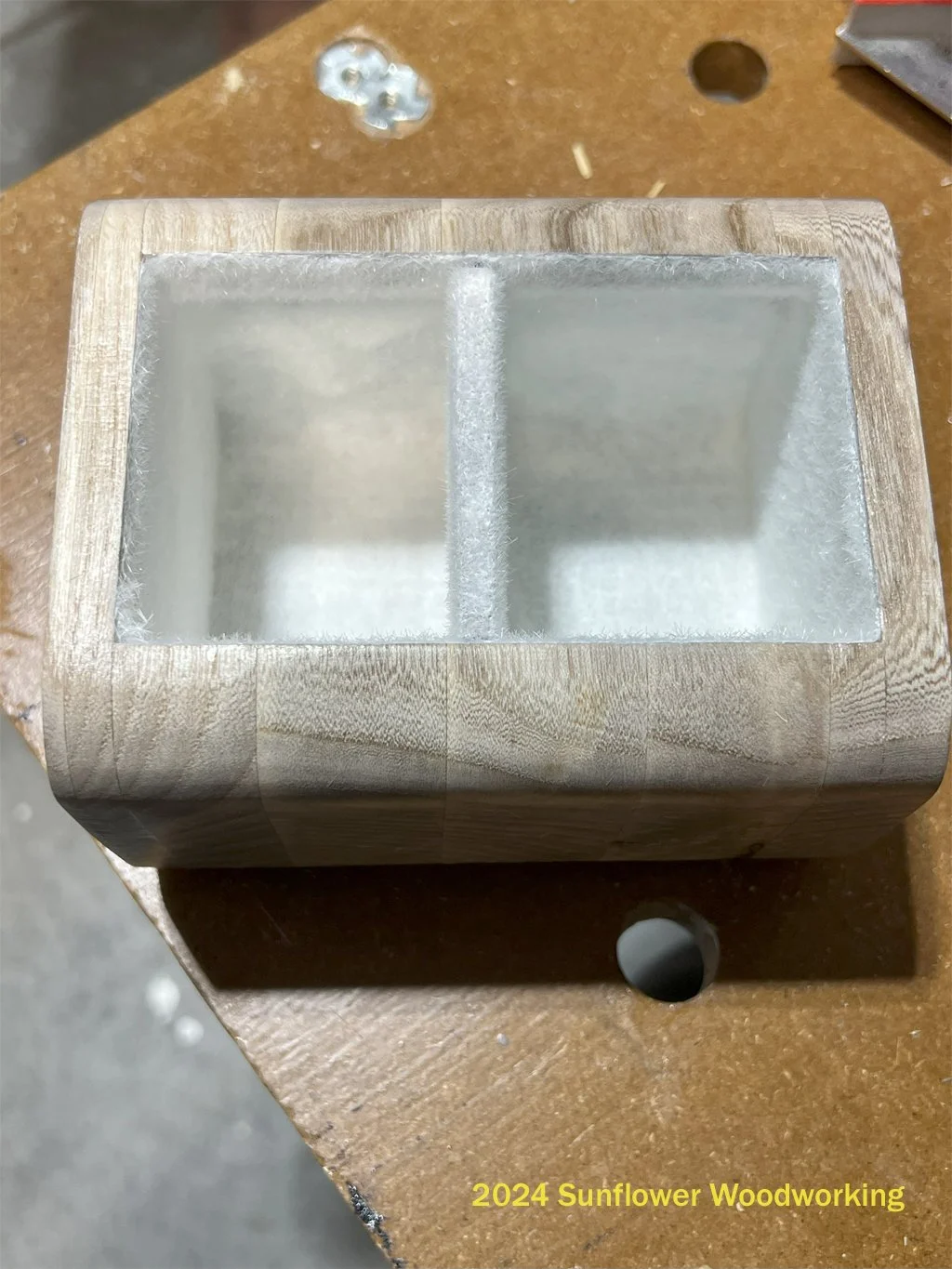

Hackberry wood has a coarse grain. It is can have green and gray hues in its grain, which is why we picked it for our first bandsaw box. This was made for a very special fashionista who needed a nice place to store her jewelry. She also wanted an open “tray” on top where can place bracelets and other trinkets. We used white acrylic paint to adhere the white flock to the insides of the drawers to add a soft texture. Finished with white-tinted polycrylic it has a nice, smooth, matte finish.

What did we learn?

Well, it was our first bandsaw box. If you search the web for “bandsaw” boxes, you will see an enormous variety of designs. These boxes combine the art of flow and design with the skills of working wood. We kept our design simple for this first go-round, but have since moved onto other, more complex designs (okay, maybe not too complex yet). The approach we like is to make the design “seamless” so that you cannot see where the blade cut to create the shapes inside of the box.

Hackberry was also new to us. It is a little different than some of the hardwoods with which we worked because of the coarse grain. It took us a slightly different cutting and sanding technique. The coarse grain can pull off in strands from time to time, so we try to stay in-between the lines when we can.

Then there is the flocking. There are different types of flock. This one is nice, but we have since found crushed velvet flock which is super soft. This flock added texture and color to the inside of the boxes. Instead of glue, we used acrylic paint to attach the flock. Flock is typically a powder. We apply the paint, put the drawer in a bag with some flock, and shake thoroughly. The paint helps blend the flock and fill any gaps while also acting as the glue.

The last thing we learned in this project is making custom handles. We blended pink universal dye, pearl mica powder, and pink luminescent pigment in epoxy. We poured the mix into silicone chocolate molds shaped like hearts. For the screw backing, we used stainless steel rivetnuts so we could fasten the screws to the handles. This technique opened up a whole world of opportunities for creating custom handles for future projects. Take a look at some of our other bandsaw box projects and see if you can spot them!

In Closing…

Learning something new is always so rewarding. We learned so much from this project that we have since applied to other projects and continue to refine our designs and approaches. God shows us how things intended for one purpose can serve a purpose we did not intend and this cascades across our portfolio.